Microtonal

Musical Robot

Research project on

the development of new tools for musical expression at the University

College Ghent

|

|

<Korn>

a robotic and moving Bb cornet

dr.Godfried-Willem

RAES

2008-2010

|

This musical robot belongs to the category of our more experimental instruments.

The experiment was not so much an attempt to realistically automate an existing

instrument, although it does in fact make use of an old Bb cornet and there

is an attempt to get a realistic cornet sound. In this case however, we did

not start with a mechanical design for an artificial embouchure with mouth,

lips and mouthpiece coupled to and in acoustic interaction with the tubing of

the instrument, as we have done in <So> and the first version of <Bono>,

but rather used a small motor-speaker compressor directly coupled to the cornet

via a capillary. The motor driver causes resonance in the cornet tubing, but

in this case there is no real windflow through the instrument. When a note is

requested from the cornet, the firmware will calculate the optimum valve combination

-including non orthodox fingerings- for the requested pitch. Microtonal pitches

are implemented such that the instrument is capable of performing quartertone

music, as well as a wide range of different tunings and temperaments with great

perfection. The relatively low Q-factor of the horn (compared to strings...)

as an acoustic resonator renders this very well possible. The signal generated

in the motor was shaped after a physical model of the air pressure waveform

in the mouth cavity of a player. Since there is no loop coupling from the resonator

to the generator, the sound generation mechanism is a hybrid somewhere between

synthetic/electronic and natural/acoustic. The advantage being that the reliability

of the robot becomes very high, but this is obtained at the detriment of realism.

The valves are used in this instrument to tune the fundamental frequency of

the instrument. The valves can be controlled independently from the mouth driver

frequency. They are mechanically driven by unipolar solenoids (Lucas-Ledex types

as used in our player pianos) and have a return spring. Bi-directional solenoids

would have been superior (read faster and more silent in operation due to the

absence of return springs) but we just did not have enough mounting space in

this rather small instrument.

High brass instruments in their normal human biotopes tend to move quite a

bit in space. The highly directional characteristic of these instruments make

this also an expressive valuable parameter. Thus we tried to implement movement

in two degrees of freedom in this robot: the cornet can be tilted in the vertical

plane over an angle of about 90 degrees and in the horizontal plane, it can

rotate over 180 degrees. This conforms pretty well to what human players do

in terms of movement on stage. The movements cannot be very fast however, at

least not much faster than what a real cornet player could do whilst playing.

Horizontal movement is a lot faster than the vertical movement. However, the

intention never was to render Doppler effects possible...

The electronic circuitry consists of four PC-boards:

1. Midi-hub board: This board, using a Microchip 18F2520 controller, takes

care of the Midi I/O handling and communication as well as the control of some

of the the lights and the movement of the horizontal movement stepping motor,

including the two end sensors. For these we used two Pepperl & Fuchs inductive

proximity sensors (NJ2-V3-N) . Provisions were also made for two PIR-sensors

allowing the robot to 'search' in space for moving human bodies. The output

data from these sensors can either be routed to the commands for the horizontal

stepping motor or output as a midi data stream. Circuit details can be found

at the very end of this webpage.

2. Horizontal stepping motor driver board using a Nanotec SMC42 compact microstep

constant current driver. The noisy fan was removed as well as the DIN-rail mount.

This motor

is designed for 360 steps for a complete rotation. In this robot, the motor

is driven in microstepping mode at 8 clocks for a single step.

This motor

is designed for 360 steps for a complete rotation. In this robot, the motor

is driven in microstepping mode at 8 clocks for a single step.

3. Pulse & Hold board: This board steers the three solenoids for the pistons

as well as the vertical movement stepping motor. Component population on the

board was modified to accommodate for required position sensors for the motor

movement. For position sensing in the vertical plane we first used a beautiful

antique mercury switch with 3 contacts. This switch had a glass tube in a circular

shape filled with mercury. It was designed rotate over its 6 mm axis. However,

the binary nature of this switch in combination with lost steps on motor slip

made precize positioning problematic. Thus, in 2010, we replaced this switch

with a Penny+Giles analog tilt sensor connected to the an0 analog input of the

PIC microprocessor.

The light

bulbs and LED's mapped on the midi notes 124 to 127 are also controlled by this

microprocessor board.

The light

bulbs and LED's mapped on the midi notes 124 to 127 are also controlled by this

microprocessor board.

4. Sound generator board: This board, using a microchip ds-PIC 30F3010, steers

the 15 Watt motor compressor horn driver. Note that the output transformer forms

a tuned circuit, tuned to the formant band of the cornet (1.8 kHz). The transformer

at high sound pressure levels, operates close to saturation, thus causing a

formant shift upwards. When a coil gets into saturation the inductance decreases.

This clearly nonlinear behavior of the circuit was part of the design.

The wave forms generated in the firmware on the pwm1 and pwm2 outputs of the

controller are PWM based modified sinewaves in opposite phases. The carrier

frequency is around 20 kHz.

Power supply voltages and currents:

- +12 V dc (5 A) for the valve solenoids, sound driver and lites

- -18 V dc (5 A) for the valve solenoids and the vertical stepping motor

- +5 V/ 1 A for processor boards

- +26 V/4 A for the horizontal stepping motor (non stabilized)

Midi Mapping and implementation:

Midi channel: 12 (fixed in the firmware)

Midi note range: 52 to 94. (Optimum sound in the range 66-89) Note on, velocity

is implemented and has a wide control range. The most realistic sounds are obtained

in the 100 range for the velocity byte.

Note Off commands are required, but can be dropped for pure legato playing.

Controllers:

Controller 10: (Panning) Horizontal movement controller. Value 64: center,

127->0= move left (CCW), 0->127=move right(CW). The firmware will calibrate

on each of the extreme positions (0 or 127). The full semicircle takes about

2 seconds in time. The firmware assumes that after a cold start, the cornet

is in a central position. It will recalibrate whenever an endposition is encountered.

Controller 13: [to be implemented] changes the lookup

table for the valve-pitch correspondence. The default

is 0 and conforms to an empirical mapping of valve combinations for optimal

resonant sound. Value 1 selects the theoretical valve combinations calculated

after simplified acoustic theory, values 2 and 3 select user programmable (sysex)

lookup tables. Higher values can be used to send just

any valve combination the user wants to see used for any note. The table below

gives all details:

| Ctrl 13 Value |

-1/2t |

-1t |

-1 1/2t |

remarks |

| 0 |

|

|

|

default empirical [detailed mapping] |

| 1 |

|

|

|

acoustic [detailed mapping] |

| 2 |

|

|

|

user table 1 (sysex programmable) |

| 3 |

|

|

|

user table 2 (sysex programmable) |

| 4 |

off |

off |

off |

4-7 valid |

| 12 |

on |

off |

off |

12-15 valid |

| 20 |

off |

on |

off |

20-23 valid |

| 28 |

on |

on |

off |

28-31 valid |

| 36 |

off |

off |

on |

36-39 valid |

| 44 |

on |

off |

on |

44-47 valid |

| 52 |

off |

on |

on |

53-56 valid |

| 60 |

on |

on |

on |

60-63 valid |

| other |

|

|

|

invalid |

Using this controller it is also possible to change the fingering for a sounding

note whilst it is sounding, thus rendering some sound coloration possible

without changing the actual pitch.

Controller 17 is used to control the maximum sound level during the attack

period and as a general volume controller while the note is playing. (Note that

when this controller is set to 0, you can't play any notes. For a dal niente

crescendo, start from value 1.) A good default setting to start working from

is 90.

Controller 18 is used to control the duration of the note attack. The interdependencies

of these controllers together with the velo byte is shown in the graph below:

A good default setting

for this controller is 105.

A good default setting

for this controller is 105.

Controller 19: Release controller: to be implemented.

Controller 22: Vertical inclination controller. Value 64: center, 63-0= move

down, 65-127=move upwards. Note that downward movement is twice as fast as upwards

movement. The traject is less than 90 degrees. The traject will be recalculated

whenever the endposition read by the sensor is encountered. Thus, when you request

shaky movements, the traject will be very limited because of the bouncing of

the sensor that this causes.

Controller 25: valve movement force controller. With value 18, the movement

is smooth and a bit sluggish, whereas with 127 it may get noisy but very fast.

With values below 18, valve movement may become a bit unpredictable since the

movement will depend on wear, temperature, return spring force variations and

greasing of the pistons. After a cold start, this controller will be in a default

64 position.

Controller 31: Motor speed for the horizontal motor (left-right movements).

The speed can be varied between a fixed minimum value and a (safe) and fixed

maximum value. Value 0 sets the horizontal motor to move at the slowest speed.

Controller 32: Motor acceleration/deceleration time. On cold boot this controller

is always set to 64. Larger values lead to a longer acceleration time on horizontal

motor movement starts as well as to longer slowdown times at approaching the

destination. Acceleration and deceleration are always symmetric. As a consequence,

small movements will be performed slower than longer trajects.

Controller 66: Power on/off switch (0 = off, any other value is on)

Controller 67: brings the horizontal motor to the extreme left position (parameter

value =64). The controller is a one shot and does not need a reset. Any other

value than 64 is disregarded.

Controller 68: brings the horizontal motor to the extreme right position (parameter

value = 64). The controller is a one shot and does not need a reset. Any other

value than 64 is disregarded.

Controller 70: Calibrates both the vertical movement motor to a horizontal

position as the horizontal position to a straight forward position. This command

should only be sent on a full stop of all motors, i.e. no other midi motor related

commands should be sent during this calibration. The parameter can be any non-zero

value. This calibration also takes place automatically after a cold start of

the robot. Do not use this controller in any sequenced composition.

Controller 71: Recalibrates the horizontal motor movement only and brings the

instrument back to a full frontal position. During calibration no other motor

related midi command should be sent to the robot.

Controller 90: used to select movement interactive modes. With value 0 this

feature is switched off. Possible values are 1,2 and 3. More interactive modes

may be implemented in the future. The movement data are derived from the two

PIR sensors mounted in the front of the instrument.

Controller 100: Midi output mode setting. (See further below). Defaults to

zero.

Controller 101: Midi output data rate. See below.

Controller 123: switches the sounding note off, unpowers the steppers, dims

all the lights.

Program change: not implemented so far

Lights: The lights are mapped on very high midi-notes as follows:

- note 127: triple bright white LED on pulse-hold board with PIC2 (on/off)

- note 126: triple bright white LED on pulse-hold board with PIC2 (on/off)

- note 125: Blue 6-LED light assembly, mounted near mouthpiece driver (PIC2)

(on/off)

- note 124: Harley Davidson tungsten light bulb (PIC2) (on/off)

- note 123: Bright RED led mounted on the hub board

(PIC1). The velo byte sets the flashing speed. 0= off, 127= fully on.

- note 122: Left eye blue LED's (PIC1)The velo byte

sets the flashing speed. 0= off, 127= fully on.

- note 121: Right eye blue LED's (PIC1)The velo byte

sets the flashing speed. 0= off, 127= fully on.

Pitch bend: The <Korn> robot can be used in any tuning system. In the

drawing below we give the coding example for a quartertone scale:

Most good sequencer

software (such as Cakewalk or Sonar) use the signed 14 bit format. Note that

one unit of the msb corresponds exactly to a 0.78 cent interval. To convert

fractional midi to the msb only pitchbend to apply follow following procedure:

if the fractional part is <= 0.5 then msb= 63 + (FRAC(note) * 128), if the

fractional part is larger than 0.5, we should switch on the note + 1 and lower

the pitch with msb= (1-FRAC(note)) * 128. Note off does

reset the pitch bend for the playing note!

Most good sequencer

software (such as Cakewalk or Sonar) use the signed 14 bit format. Note that

one unit of the msb corresponds exactly to a 0.78 cent interval. To convert

fractional midi to the msb only pitchbend to apply follow following procedure:

if the fractional part is <= 0.5 then msb= 63 + (FRAC(note) * 128), if the

fractional part is larger than 0.5, we should switch on the note + 1 and lower

the pitch with msb= (1-FRAC(note)) * 128. Note off does

reset the pitch bend for the playing note!

Midi OUTPUT control:

Data from the PIR sensors can be output as midi data

as well as data with regard to the position of the robot in space. A controller

(#100) has to be sent to Korn to enable midi out. This feature is meaningless

for composers using sequencing programs, but can be very welcome for composers

wanting to develop interactive applications using programming languages such

as Power Basic, GMT or even PD. The implementation is as follows:

Controller 100: Midi output mode. The data byte consist

of 7 bits (0 to 6), each used as a switch to enable/disable particular midi

output streams.

- 0 = OFF (midi out is disabled) This is the default.

- bit 0 = Left PIR sensor data is output: Left sensor

is output as 14 bit pitchbend on midi channel 0. The data is an 8 bit value.

Sampling rate can be set with ctrl.101

- bit 1 = Right PIR sensor data is output as pitchbend

on midi channel 1. The data is an 8 bit value. Sampling rate set with ctrl.101.

Sampling rate maximum: 154 S/s

- bit 2 = Motor position monitoring. The data covers

the entire traject (0 - ca.. 1480). Output is on midi channel 2. Sampling

rate 38 S/s

- bit 3 = Monitoring of the left movement proximity

sensor. The data is 10 bits. Midi channel 3. Sampling rate 154 S/s

- bit 4 = Monitoring of the right movement proximity

sensor. The data is 10 bits. Midi channel 4. Sampling rate 154 S/s

- bit 5 = Monitoring of the loopspeed in the firmware.

Output is in pitchbend format with only the lsb of the timer0 value (for debugging).

Midi channel 5. The output data rate is the loopspeed plus the time required

for the midi output itself. (ca. 1 ms) [implemented for firmware debugging

only]

- bit 6 = Monitoring of the Soll position for the motor

(destination value). Midi channel 6.[implemented for firmware debugging only].

Other values are implemented for internal research, firmware

debug and development purposes. Note that on start up and calibration, the available

motor traject in steps is always output using the pitchbend format, even when

controller 100 is set to zero. The traject is in the order of 1480 steps.

Controller 101: Use to set the data rate for the midi output of the PIR sensors.

The values accepted for this controller are between 1 and 8. The default value

is always 4. The meaning is as follows:

- data rate ca. 1.2 Hz value = 1

- data rate ca. 2.4 Hz value = 2

- data rate ca. 4.8 Hz value = 3

- data rate ca. 9.6 Hz value = 4

- data rate ca 20 Hz value = 5

- data rate ca 40 Hz value = 6

- data rate ca 80 Hz value = 7

- data rate ca. 160 Hz value = 8

Technical specifications:

- size: height 800 mm, depth 400 mm, length 400 mm.

- Flightcase size: 950mm x 590mm x 390mm.

- weight: 17 kg.

- transportation: needs its flightcase. Cannot be taken as luggage in airplanes,

since the weight with case is over 35kg.

- Power: 230 V ac / 150 W

- Note: on cold boot is is mandatory that the cornet is positioned in its

central position, without touching any proximity sensor.

- Tuning: based on A = 440 Hz (within 1 cent). The tuning can be adjusted.

- Ambitus: 52-96 (optimal range: 58 - 87)

- control: MIDI-input, 3 MIDI-Thru, 1 MIDI-Out. (UDP port to be implemented

later)

- Insurance value: 8.500 Euro.

Design and construction: dr.Godfried-Willem

Raes

Collaborators on the construction of this robot:

- Kristof Lauwers (GMT implementation)

- Johannes Taelman (dsPIC coding)

- Yvan Vander Sanden (controller testing)

Music composed for <Korn>:

- Sebastian Bradt "Barbiefication" (for <Korn> and <Xy>)

(2008) [MP3 download]

- Godfried-Willem Raes "Sires Hands" for <Sire> and <Korn>

and a performer with the Handy One interface

- Godfried-Willem Raes "Just

Calls for Brass" (in just intonation, with <Bono>, <Heli>

and <So>)

- Yvan Vandersanden "Interaktief stuk voor <Korn>, <Snar>

en Wii kontroller" (2009) [MP3

download]

- Godfried-Willem Raes "Gesti for Korn", quadrada study #19 for

a naked performer and <Korn>. Staged in collaboration with a.rawlings

(2009)

- Kristof Lauwers "Picrada Study for Korn".(2010)

- Godfried-Willem Raes "Moves for Korn". Staged in collaboration

with Dominica Eyckmans (2010).

- Godfried-Willem Raes "Zwiep & Zwaai". (2010)

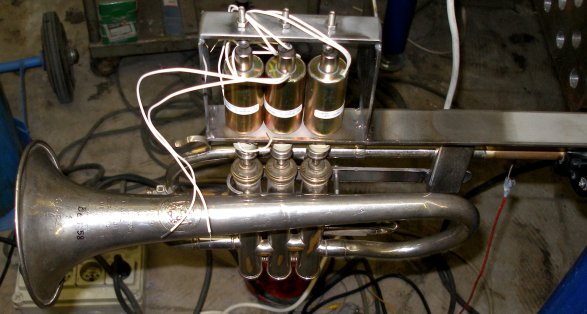

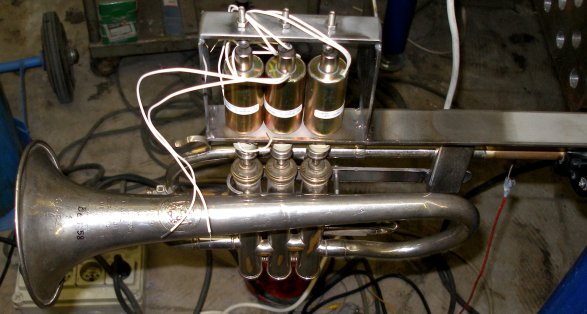

Pictures taken during the construction in our workshop:

Nederlands:

<Korn>

De overgrote meerderheid van de muzikale robots die we ontwikkelden

voor 2007, waren elk voor zich pogingen om bestaande akoestische instrumenten

zo getrouw mogelijk te automatiseren in zoveel mogelijk aspekten van hun bespeling.

Daartoe mimeerden we zoveel als mogelijk de menselijke bespelingswijze van deze

instrumenten. Het <Korn> projekt wijkt van dit opzet in hoge mate af.

Hier was het helemaal niet onze bedoeling een mimetisch bespeelde automatische

kornet te bouwen (immers, een automatische Sousafoon -<So>- hadden we

reeds met redelijk sukses voltooid, waardoor een automatische kornet niet direkt

een nieuwe verwezenlijking zou zijn). Niettemin maakt deze robot wel degelijk

gebruik van een oude Sib kornet die hier evenwel in eerste plaats dienst doet

als afstembare resonator in een instrument dat verder alleen werd gekoncipieerd

om min of meer realistische kornet-geluiden op een plastische en kontroleerbare

wijze te kunnen produceren. In dit ontwerp werd uitgegaan van het simuleren

van de drukvariaties in de mondholte van de bespeler en in het mondstuk middels

een elektronisch aangestuurde motor driver, zoals gebruikt in kleine megafoons.

Wat hier ontbreekt is de terugkoppeling met de resonator die het instrument

zelf eigenlijk is. Het instrument fungeert hier als een passieve resonator en

is niet via een dynamische regeling gekoppeld aan de eigenlijke toonvorming.

Daardoor krijgen we enerzijds een heel hoge betrouwbaarheid, maar anderzijds

dan weer een toch wat synthetisch klinkend klankresultaat met weinig of geen

artefaktische bijgeluiden en een eerder stereotype gelijkmatige artikulatie.

Wat we van bij het ontwerp evenwel zeker geimplementeerd wilden zien was een

ruime gamma aan mogelijkheden op mikrotonaal gebied. Zowel kwarttoonsmuziek

als muziek in de platonische juiste boventoonsstemmingen diende perfekt speelbaar

te zijn. Om die reden kan deze robot heel goed overweg met alle niet-standaard

vingerzettingen. Akoestisch gezien wordt dit mede mogelijk gemaakt door de relatief

lage Q-faktor van de licht konische toeter gezien als akoestische resonator.

De ventielen werden geautomatiseerd met unidirektionele elektromagneten,

helemaal naar plan en opzet zoals toegepast in de eerste

versie van <So>. We hadden liever bidirektionele magneten gebruikt,

maar daarvoor vonden we gewoonweg geen plaats in een zo klein instrument als

de kornet. De ventielen werken dan ook met de gewone terugslagveren.

De elektronische schakeling bestaat uit enkele afzonderlijk funktionele

boards:

1. Midihub board; Dit board, uitgerust met een 18F2520 PIC-controller

van Microchip, staat in voor de midi-kommunikatie en voor de besturing van de

horizontale stappenmotor. Twee ingangen worden gebruikt voor het inlezen van

de horizontale positiesensors. Daarvoor werden aanvankelijk mikroswitches met

lange naaldhefbomen in veerstaal gebruikt, maar die werden in 2010 vervangen

door induktieve NAMUR proximity sensors van Pepperl+Fuchs. (NJ2-V3-N). Deze

sensoren worden analoog door de microprocessor ingelezen, waardoor we geen problemen

meer hebben met bouncing. Twee andere ingangen worden gebruikt voor het inlezen

van de data afkomstig van twee pyrodetektoren (PIR-sensors). Deze laten toe

de horizontale beweging van de kornet een menselijk lichaam in de ruimte te

laten volgen.

2. Stappenmotor besturings board, waarvoor gebruik werd gemaakt

van een Nanotech SMS42 module.  De motor, een type met 360 stappen per omwenteling, wordt bedreven in microstepping

mode aan 8 kloktikken per stap, wat een erg vloeiende beweging mogelijk maakt.

De motor, een type met 360 stappen per omwenteling, wordt bedreven in microstepping

mode aan 8 kloktikken per stap, wat een erg vloeiende beweging mogelijk maakt.

3. Pulse-Hold board voor de besturing van de ventielen evenals

voor de besturing van de vertikale stappenmotor. Dit board maakt gebruik van

een Microchip 18F4620 controller in 40pins DIL behuizing. De bestukking van

het board werd enigszins gewijzigd om de beide noodzakelijke inputs voor de

eindsensor van de motor mogelijk te maken. Voor deze sensor gebruikten we aanvankelijk

gebruik van een cirkelvormige driepolige kwikschakelaar voorzien van een 6 mm

as. Het onderdeel dateerde van vlak voor de tweede wereldoorlog.. Door de slip

van de motor in kombinatie met het louter binair karakter van de sensor kregen

we echter af te rekenen met problemen in het juist positioneren van de kornet.

Daarom vervingen we de kwikschakelaar in 2010 door een hellingssensor van Penny

& Giles (STT 280/60/P2) . Deze

sensor wordt analoog ingelezen door de A0 analoge ingang van de mikroprocessor.

en laat een erg nauwkeurige positionering toe.

De lampjes

en LED's gemapt op de noten 124 tot en met 127 worden ook door deze mikroprocessor

bestuurd.

De lampjes

en LED's gemapt op de noten 124 tot en met 127 worden ook door deze mikroprocessor

bestuurd.

4. Klankproduktieboard: Dit board werd uitgerust met een 30F3010

ds-PIC kontroller van Microchip. Dit board heeft ook een midi-out, dit in eerste

plaats omwille van de debug mogelijkheden. Opgemerkt moet worden dat de uitgangstransfo

hier een afgestemde kring vormt met een resonantie rond 1.8 kHz, overeenkomstig

de gewenste formant voor een kornet.

Aangezien een kornet op zich genomen een vrij klein en licht instrumentje

is, kwam de idee bij ons op om het ook meteen enige mate van beweeglijkheid

mee te geven. Deze beweeglijkheid behoort immers ook tot het typische geluid

van de hoge koperblaasinstrumenten, die immers zonder uitzondering een sterk

direktionele akoestische afstraling hebben. Hiermee konden we meteen Toshiba

& Yamaha de loef afsteken, want hun bewegende trompetspelende robot -die

wel zowat alle kranten haalde- is vals! Het geluid komt immers uit een luidspreker

uit de borstkas van de robot trompettist. Ook wilden we onze robot graag zo

gaan bouwen dat hij het zou vertikken om debiele muziek te spelen... Dat is

echter helaas nog steeds vapourware. Horizontaal kan onze robot 180 graden bewegen,

en vertikaal 90 graden. Hiermee mimeren we heel goed wat menselijke spelers

op het podium doen. Een erg hoge snelheid konden we voor deze bewegingen evenwel

niet realizeren, wat niet wegneemt dat die snelheid (horizontaal) zeker niet

moet onderdoen voor die van een menselijke bespeler. De vertikale beweging is

door de gebruikte wormwieltechnologie aanzienlijk trager. Het was dan ook niet

de bedoeling Doppler effekten mogelijk te maken.

De <Korn> robot werd gemonteerd op 3 rondom beweeglijke

zwenkwielen voorzien van remmen. Wanneer de remmen niet worden vastgezet tijdens

het spelen, kan de robot zich als gevolg van de eigen bewegingen ook wat over

het podium verplaatsen... een leuk maar eigenlijk onvoorzien neveneffekt.

Construction & Research Diary:

- 04.01.2008: first experiments with the sound generator devices: horn motor

compressors.

- 07.01.2008: Cleanup and adjustment of the cornet valves

- 08.01.2008: First experimental construction of a motor horn driver, taken

from an old megaphone. The sub-octave sounds (the real fundamentals of the

cornet) cannot be made to sound really good. Hence we decide to drop them

altogether.

- 10.01.2008: Construction carrier plate for the valve solenoids with 19 mm

holes in stainless steel.

- 12.01.2008: TIG welding work on solenoid assembly. Design of a holding structure

for the cornet such that we leave the possibility for the instrument to move

freely, open.

- 13.01.2008: Welding works on the cornet holding structure. Design of the

motor driver holder. First workshop pictures taken and added to this webpage.

- 14.01.2008: Selection of a suitable stepper motor for the horizontal movement.

For vertical movement, we could simply use a heavy solenoid combined with

a spring. These features will have serious consequences for the design of

the power supplies! Purchase of ball bearings for two axis of movement. Vertical

inclination will require a force of ca. 50N.

- 15.01.2008: Further design of support structure. Suitable stepper motor

maybe AIMS 24 V/ 100 Ohm/winding 4-phase motor with worm-wheel gears, if we

use a tiny wound steel or nylon cable for the vertical movement. This motor

comes from a recycled old Japanese photocopier. The advantage of this mechanism

is that no power on the motor is required to hold the cornet in any given

position. Problem to be solved: how can we safely connect the steel wire to

the barrel.

- 16.01.2008: Plasma cutting of ground plate. Welding support for vertical

movement motor. Design for wheels of the support block.

- 17.01.2008: Start cutting and welding works for the horizontal movement

mechanism. The main chassis is ready now, included the three wheels with breaks

under the equilateral triangle bottom plate. Heavy duty connector found for

the removable connection between moving upper part and the electronics on

the base plate. Toroidal transformer selected for power supply: 2x 12 V/ 5

A. This transformer can be mounted under the base plate.

- 18.01.2008: Turning work on horizontal dented wheel. Mounting of toroidal

transformer underneath. Drilling holes for the horizontal stepping motor mounting

bolts. Discussion of the sound mechanism and its PIC implementation with Johannes

Taelman.

- 19.01.2008: Horizontal motor mounted and adjusted. Positioning of PC -boards.

Mounting holes drilled. Threads for motor mounting (M5 studs) welded on bottom

plate. Two 90/60/30 triangles in 3mm thick stainless steel plate welded to

end point. These serve for avoidance of mechanical resonance's and for mounting

of the horizontal stepping motor controller. All welding performed with frequent

intermediate cooling with compressed air to avoid warping.

- 20.01.2008: Mounting and wiring of power supplies. Mounting of all required

PC-boards, except DS-PIC board. Midihub board soldered with component values

documented below (see end of this webpage). Mosfets exchanged for IRLZ44 types.

- 21.01.2008: Interboard connectors made. Design of end position sensors for

the steppers. Electrical testing of midihub board and motor controller board.

- 22.01.2008: Schematic for pulse-hold board redrawn. Soldering and component

selection and placement on pulse-hold board. Stainless steel piece bend, sawn,

polished and drilled with eyelet for the vertical movement. Mounting holes

24 mm apart, for M5 bolts. Bottom part large connected wired. Six ultrabright

LED's mounted on pulse-hold board, mapped on notes 126 and 127.

- 23.01.2008: Rotary mercury switch applied for vertical movement sensing

and positioning. The use of this part makes the robot illegal as an industrial

product in most of the civilized world. However, we had the part on our shelves

for at least some 40 years, before we finally found a good application for

it. Moreover, the part comes from military radio equipment from just before

the second world war. Orange light bulb (from a motor bike, probably Harley

Davidson) mounted on vertical motor assembly. This bulb has 10 Ohm cold resistance.

It draws quite a lot of current from the 12 V supply. Note that the mounting

uses an insulation feed through since the metal of the holder is connected

to one of the supply leads.

- 24.01.2008: All wiring finalized, except the ds-PIC board for the sound

driver. Microswitches for end-detection on horizontal movement added. Power

supplies tested o.k. Design of the ds-PIC board. Construction of a first prototype,

using a small audio transformer.

- 25.01.2008: ds-PIC board finalized and mounted. <Korn> is ready now,

except for the (ordered) 25 mm mechanical precision ring to hold the gear

wheel on the horizontal movement axis. The PIC programming works with Johannes

Taelman can take off... First firmware version for the PIC-controllers uploaded.

- 26.01.2008: First evaluation and test session. The code for the stepping

motors is still missing in the PIC firmware. The valve firmware works nicely,

the lights also. The ds-pic seems not working unless we reset it by applying

a pulse to pin1. This type of PIC appears to be extremely sensitive to spikes

on the supply lines. We remember having met similar troubles in the design

of <Bono>. The power delivered to the driver is 280 mW, when the power

supply voltage is 5 V. Thus, this voltage can safely be raised quite a bit.

Optimum sound is now obtained with following controller settings: Velo=38,

C17 = 127, C18=127. The calculated lookup tables correspond perfectly to optimum

horn resonance. So, there is no need to implement user lookup tables here.

However, different fingering can contribute to a more lively sound.

- Experiments with the ds-pic board: We raised the power supply to 24 V and

with a 10 Ohm series resistor, and connected it to our driver circuit. With

maximum controller settings, we have a voltage drop over the resistor of 11.4

V, hence a current of 1.14 A. Such a current clearly saturates (...and heats)

the transformer, with quite interesting sonic artifacts as result. An RC or

even LC combination might even sound better here, since it could give us the

possibility to tune it to the characteristic formant of the cornet. We tried

this, but the first results were very disappointing. So we conceived another

approach and calculated the integer number of the harmonic on the sounding

note that falls as close as possible within the formant of the cornet. For

this frequency band we assumed 2800 Hz, a value taken from literature on old

analog eletronic organ design books for the formant filters in cornet registers.

Obviously we need either measurements of our own, or more reliable sources.

The result of this calculation was added to the file describing the calculated

fingerings: lookup tables for <Korn>

(its a .txt file, not html!).

- 27.01.2008: The addition of a sub-partial corresponding to the base frequency

for each played note at about 30 dB below the level of the main pitch, contributes

greatly to a more realistic sound. Further experiments with the hardware circuit

led us finaly to the adoption of a hardware formant filter, designed around

the primary of the output transformer on the ds-PIC board. To do this, we

left the usual protection diodes (BYV32) out altogether and fitted a capacitor

calculated and measured to give a resonant frequency around 1.8 kHz. Soundwize,

this proved to be a major improvement, rendering the implementation of additive

formant components in the generated waveform unnecessary. If further filtering

and non-linear circuitry is required, it can now be done on the secondary

side.

- 28.01.2008: We digged up a spare part for the motor driver, in case the

one mounted gets overloaded in the process of the experiments. First work

on an algorithmic demo piece for <Korn> coded in GMT.

- 29.01.2008: Measurements of the real partials as compared to the platonic

ones shown here:

- 30.01.2008: Measurement and evaluation session by Kristof Lauwers. Pitch

bend range is now -50 to +50 cents.

- 01.02.2008: Dented wheel fixed on vertical column with pointed M3 bolts.

Solenoids definitive mounting and fixing. Replacement of felt washers inside

the pistons in order to silence their mechanical operation. Experiments with

LC-circuits in the primary circuit of the motor driver.

- 02.02.2008: Further experiments with formant filters in the drive circuit.

Whatever we attempt, it remains a very electronic and dull sound. The clicks

at the on- and offsets of a sound correspond to the tap tones on the mouthpiece.

The onset should definitely get a noise burst.

- 06.02.2008: Still a bit handicapped by pretty poor sound production and

lack of movement, <Korn> will already participate in a few pieces on

tomorrow's M&M concert.

- 08.02.2008: Preliminary premiere of 'Barbiefication' by Sebastian Bradt.

- 15.02.2008: Work session on DS-PIC code: clicks and glitches removed both

on note-on and note-off. Softer attack implemented. Wind-noise added. Octave

fault corrected.

- 16.02.2008: Composers manual updated in accordance with the latest midi

implementation.

- 21.02.2008: <Korn> participated in the mini-M&M concert in Schaarbeek

(Brussels).

- 01.05.2008: Further worksession on horizontal stepping motor for movement

with Johannes Taelman. Not yet working. We seem to be plagued by bugs...

- 02.05.2008: Horizontal movement is working now, under controller 21. Calibration

is automatic and happens everytime one of the endpositions is reached. Acceleration

curve and stepping speed are automated and not user programmable. The firmware

is optimized for low noise, smoothness of movement and sufficient torque.

Movement speed is 45 degrees of rotation per second. The controller works

positional: 0 corresponds to fully CCW and 127 to fully CW.

- 03.05.2008: GMT testcode for Korn updated.

- 10.05.2008: Working session with Johannes Taelman: vertical movement and

revision of the valve code. The first version was written in assembly, but

for this version we will use the Pic-C compiler. Controller 70 implemented

for vertical movement calibration. Vertical movement now works, but we still

have to rewrite the valve code and the relevant lookups. Stepping pulses on

downward movement are now. ca.20ms, whereas upwards they become 40ms. The

firmware uses only the velo-pulse outputs, so the hold mosfets are not used.

Because of the mechanical construction, the motor never had to develop a holding

torque, hence we could drop these components from the implementation.

- 12.05.2008: Working session with Johannes Taelman: code for velo-pulses

on valves ported to C on PIC2. To be done: Sysex-lookups for fingerings, further

improvement of the generation.

- 13.05.2008: 350 mA current source circuit built for 1 W super bright LED.

Forward voltage drop is 3.2 V as measured. Although the LED itself is pretty

small, if you take the complete required circuitry and cooling components,

there is something ridiculous about these components since at the end of the

bill, a normal tungsten light would have been both simpler, smaller and cheaper...

Light output is 10 lm, wavelength 470 nm

- 15.05.2008: 1W blue LED circuit mounted near mouthpiece driver and mapped

on note 125. However, it seems to cause glitches and resets on PIC2, caused

realignments of the vertical movement...

- 16.05.2008: Calibration command must still have a firmware bug. It should

read and monitor the mercury switch -after debouncing- to decide in what direction

to start rotating for alignment.

- 17.05.2008: An extra command should be added in the motor firmware: freeze

movement: ctrl. 71 (switch). This should work at the same time for the horizontal

and for the vertical movement. (PIC1 and 2). The freeze command should cancel

any ongoing movement.

- 12.08.2008: Consistent erratic behaviour. Sometimes actions take place without

any command... This led today to a complete burn out of the Harley Davidson

light armature. We replaced the lamp socket (was bayonet) with a standard

10mm screw socket and fitted a 12-15 V/160 mA tungsten bulb. After this repair,

it seemed some mosfets on the pulse hold board burned out... More work to

be done. Probably the solenoid driver mosfets burned out. There must be either

bugs in the PIC2 firmware or some other hardware failure.

- 06.09.2008: Further repair work on Korn. The Lucas-Ledex solenoid for the

first valve burned out and shows up a short circuit situation. We replaced

the solenoid. Tests under GMT control. Strange behavior observed from the

solenoids: bouncing... either something goes wrong with the PIC based timers

or the (Hold voltage) power supply is extremely unstable. First suspect to

examine: +5 V, then +12 V.

- 07.09.2008: Debug session. The faults are reproducible. Probability that

they stem from unstable +5 V is high. However, so far we couldn't see any

glitches on the scope. However, the +12 voltage shows up very high oscillation

( 4 Vpp), increasing with the load with period in the 5 microsecond range

(ca. 200 kHz). This oscillation disappears when we place a 2 mF electrolytic

over the output of the LT1084-12 regulator. The pulses in the ground return

current could be at the origin of the unstable behavior. The oscillation could

also explain the erratic behavior of the vertical stepper, since its mercury

sensors are fed with the same +12 V. Piher 2 mF/16 V elco and 1 uF ceramic

soldered into board. Now every thing seems up and working again. The 1 W blue

LED however seems not to have survived the failures...

- 08.09.2008: Korn monitored over longer timespans: calibrations on the vertical

motor still do happen at about every 5 minute rates. We have been monitoring

the 5 V supply and suspect it fluctuates at a very low frequency.

- 13.10.2008: New acoustic impedance convertor turned on the lathe. This brass

piece was made from the original cornet mouthpiece.

- 20.11.2008: The erratic behavior is persistent. We will have to replace

the Chinese SMPS (Sunpower) by a more sturdy modular design. Some more work

done on the sound determining circuitry. The <Bono> recipe applied to

Korn. (A single diode on the transformer primary). The capacitor has to stay

as it was. We now feed the driver from the available +12 V supply. The transformer

is heavily in overload, so we should look out for a more powerful part.

- 21.11.2008: To do: add an extra 5 V power supply for the horizontal stepper;

replace bright blue LED; search for a better audio transformer. Research and

measurement session on a MCE E217T3F precision toroidal multitap transformer

(Order number: 10018709), recycled from military aircraft.

- 22.11.2008: Origin of the erratic behavior traced down to very odd behavior

of the high power LED and its current drive circuit: the LED failed but still

caused very short very high current spikes on the 12 V supply, too short to

activate the current limits but so high that we could observe very large spikes

on the ground return leads, causing intermittent brown outs on the 5 V supply

feeding the PIC processors. We replaced the LED with a new assembly of 6 bright

blue LED's each drawing a current of only 11 mA. Mounting of the MCE multitap

transformer on the backside of the Korn chassis. This entails the addition

of a new welded chassis element. Circuit drawings adapted to the newest wiring.

The horizontal motor looks like working, despite the low power available from

our newly added 5 V dc power supply.

- 23.11.2008: Welding work on the construction and mounting of the new chassis

elements (carrier structure) for the MCE precision transformer. Capacitor

across transformer primary increased from 470 nF to 2.2 uF (bipolar). The

amplitude is now a lot more constant over the entire compass. Intermittent

oscillations on the pulse-hold pic board still occur. Ferrite RFI snubbers

fitted on the most important cable bundles. We suspect a bug in the implementation

of the very slow counters in the pulse-hold PIC firmware. Bug discovered in

the dsPIC firmware: Pitch bend is not reset on reception of a new note as

it should!

- 24.11.2008: Coding example worked out for quartertone scales:

GMT code and just intonation examples for Korn debugged.

GMT code and just intonation examples for Korn debugged.

- 26.11.2008: Test code for ctrl 13 added in GMT test by Kristof Lauwers,

for examination of the optimum fingering tables. However, ctrl. 13 is yet

not implemented in the pulse/hold board.

- 18.12.2008: <Korn> has an important part in my just intonation composition

"Just Calls for Brass".

- 21.12.2008: Further experiments with the tone production. Parallel capacitor

over the toroidal transformer changed again to 220nF, this capacitor must

be a high voltage type (100V). New power supply mounted for horizontal stepping

motor: now 9 V /1.6 A. This modular supply however, cannot cope with the pulsed

load from the stepper...

- 22.12.2008: New testcode written for the stepper motors. XP Power ECL25US09-E

power supply ordered from Farnell. This type should deliver 2.8 A at 9 V with

allowable peak current of 3.64 A.

- 23.12.2008: New power supply has arrived. We immediately build it in and

tested: the horizontal motor now behaves fully the way it should.

- 02.01.2009: The somewhat shaky behavior of the vertical movement motor is

persistent.

- 17.01.2009: Debug session on the firmware for the pulse/hold pic. The code

shows up some quite unpredictable behavior: at times the velo-pulse length

has jitter and may even double. The firmware had a tendency to crash for no

apparent reason. We temporarily disabled the code for the vertical motor.

The horizontal motor code (PIC1) must have some bugs as well. It does not

switch of motor power on reaching an end position.

- 28.01.2009: Apparently the sound driver died from overloads. Fortunately

we could recycle an identical driver from another Realistic power horn 8 Ohms/

8 W. After the replacement, Korn is working again, but when we measure the

maximum signal over the driver, it appears at 12 V that the overload is evident.

However, sound level is still way too low. We have to recheck the wave form

carefully...

- 01.02.2009: Further research on sound production in Korn. The sound gets

a lot better with a diode parallel over the otherwise not used secondary tap

on the transformer in combination with the 8 W driver. However, after constructing

an entirely new impedance converter on our lathe, adapted to a 15 Watt full

range driver, the sound became much better if we replace the diode with a

2.2 uF capacitor. This change also gives us a somewhat better dynamic range

as well as a better overload safety margin. Another minor, but nevertheless

most welcome, side effect of the new motor driver is that the instrument is

now mechanically more in balance over its axis of movement, thus relaxing

the forces to overcome by the vertical stepper motor.

- 02.02.2009: Demonstration of the renewed Korn for the collaborators. Evaluation

session.

- 05.03.2009: <Korn> on the road to Lille (France). It's only the second

time he is allowed to leave the logos building.

- 07.04.2009: horizontal movement sensors improved by mounting an adjustable

sensor-pin.

- 25.04.2009: Programming session with Johannes Taelman on the gestures for

<Korn>. Deep measurement and analysis reveals that to a large extend

problems with erratic behavior is due to spikes on the midi input signal,

stemming from the Midiman 2x2 device. The 4 port device does not show up this

problem. The erratic behavior can be predicted as soon as the green midi-monitoring

LED on the hub board glows slightly with the midi in cable connected but no

midi-data sent. To a large extend this misbehavior is due to the laptop power

supply.

- 26.04.2009: Horizontal movement tests.

- 02.05.2009: Worksession on the movement code with Johannes Taelman. Horizontal

and vertical movement is now well implemented. User fingerings also, using

controller 13. Lookup tables using sysex commands for fingerings are as yet

to be implemented.

- 03.05.2009: Testcode written for gesture tracking using the quadrada interface.

- 12.05.2009: Photoshoot with Korn.

- 13.05.2009: There must still be a bug in the midihub PIC firmware that causes

it to crash. This is the PIC responsible for the horizontal movement. Premiere

of 'Gesti for Korn' with a.rawlings.

- 15.05.2009: Loose cable on upperpart accidentally hitting the end switch

remedied. Kristof Lauwers and Yvan Vandersanden adding and debugging movement

code for Korn.

- 16.05.2009: Demonstration of <Korn> at Technopolis, Mechelen (Robocup).

- 23.05.2009: Debug session on the firmware for the horizontal motor controlling

PIC-microcontroller. The inherent hysteresis of the end-sensors caused logic

trouble. The bizarre crashes of the PIC every so often, are to be examined

further. They seem related to very high midi data rates.

- 24.05.2009: 'Gesti for Korn' rechecked with the Quadrada interface.

- 21.01.2010: Transportation bed made for <Korn>, not yet a complete

case.

- 22.01.2010: <Korn> travels to Breda for a concert...

- 12.02.2010: <Korn> is off to Hasselt for the Boink! festival there.

- 09-10.10.2010: <Korn> plays on the opening of the STAM museum on the

Bijloke campus: 12700 visitors...

- 26.10.2010: Start redesign of the horizontal movement mechanism: hardware

and firmware. Considering to add a Penny & Giles sensor for the vertical

movement as well, the same type as we just used for our <Ob> robot.

- 27.10.2010: Old stepper motor controller for horizontal stepper removed.

This will be replaced with a Nanotec SMS42-2 microstepping motor controller.

In the new design we will mount two PIR sensors for human movement detection.

- 28.10.2010: Two PIR sensors mounted. Midi hub circuit redrawn and rebuild.

As to the end sensors we selected Pepperl+Fuchs NAMUR types (NJ2-V3-N) as

we can operate these from the 5V supply and they have a reasonably large analogue

traject (ca. 6 mm). We designed a new sensing stave for Korn's central axis,

the pivoting part being made from weak iron. This will at the same time work

as a mechanical endstop.

The new parts can be seen on the picture. The applebluegreenish blocks are

the Pepperl+Fuchs sensors.

The new parts can be seen on the picture. The applebluegreenish blocks are

the Pepperl+Fuchs sensors.

- 29.10.2010: Mounting work on the new components on the chassis.

- 30.10.2010: Fine adjustment of sensors and mechanism. Firmware works.

- 01.11.2010: First working version of the firmware more or less ready. Calibration

runs fine now.

- 02.11.2010: Voltages checked for stepping motor: without load: 27 V, with

running motor: 24 V. Now at firmware version 1.5. There are still some problems

with intermittent motor stops. The PIR-interactive coding needs some improvement

still.

- 03.11.2010: Firmware version 1.9: Stuttering bug killed. PIR coding now

works but there is still place for improvements. Midi implementation updated.

There is still a weakness in the dsPIC coding: this PIC crashes under unknown

circumstances. It may be related to induction spikes from the stepping motor.

- 04.11.2010: Further PIR testing. Controller 32 added to control the acceleration

curve for the horizontal motor. Controller 101 added for data output rate

control. Horizontal position controller number changed: now #10, the standard

panning controller in MIDI. As to the lights, we now also implemented automatic

flashing using the velo byte in the appropriate note on command. Firmware

version 2.0 now.

- 05.11.2010: 2 blue LED lights added as 'eyes'. Each 'eye'consists of 3 high

brightness blue LED's. Power consumption: 60 mA for each 'eye'. Mapping on

midi notes 121 and 122.

The PIR sensors as well as the new 'eyes' can be seen on the picture.

The PIR sensors as well as the new 'eyes' can be seen on the picture.

- 06.11.2010: Some minor fixes in the firmware again. Version 2.1 now.

- 07.11/2010: Deceleration on approach of final position now also implemented

in the firmware. Version 2.3 now. Controller 32 can be used to control the

acceleration/deceleration time.

- 14.11.2010: Cylinder for the vertical movement changed to 8mm diameter.

There is a lot more torque available now. This entails changes in the vertical

movement firmware.

- 15.11.2010: Penny & Giles tilt sensor mounted to replace the mercury

switch.STT 280/60/P2. Cornet fixed

in place with some silicone kit, as it had a tendency to move in its holder.

- 29.05.2011: Version 2.4 code revision for the midihub board, 18F2520 chip.

Periodicity in timers improved. Code optimised for speed of performance. Tests

run o.k. now and performance has indeed improved. Code revision session with

Johannes Taelman on the valve-control PIC, a 18F4620: vertical movement traject

improved and Penny & Giles sensor implemented.

- 06-09.10.2011: <Korn> presented and demonstrated on ArtBots Gent 2011

in the UFO building of Ghent University. It's been up and running for three

days in a row without any interruption.

- 09.10.2011: <Korn> received the Artbots award for the most succesfull

robot.

- 22.11.2011: Glissando playing now fully implemented in GMT

- 18.12.2011: <Korn> presented at the Childrens University, held on

the praemisses of the Ghent Conservatory.

- 14.03.2013: Start construction of a flightcase for <Korn>. This is

how the robot fits on the bottom of the case:

- 15.03.2013: Case under construction:

- 16.03.2013: Flightcase for <Korn> finished. It can now safely go on

the road in a truck. Case sizes are: 950 x 590 x 390

- 20.04.2013: <Korn> survived the trip to Glasgow very well! We expect

him back in Ghent on monday 22nd of april.

- 23.04.2013: Korn came back in good shape.

- 09.10.2013: <Korn> left this morning for its appearance on the Venice

Biennale on october 12th...

- 03.11.2013: <Korn> presented in Bozar for Zonzo.

- 05.11.2013: Connecting rope for vertical movement replaced as it got all

tangled and worn out.

- 02.03.2014: <Korn> makes his appearence at Concertgebouw Brugge on

the notation festival, together with <Snar> and the Player Piano.

- 18.10.2015: <Korn> played at the musica composer workshop in Neerpelt.

- 05-08.11.2015: <Korn> played four days continuously at 30CC in Leuven,

Rode Hond Festival.

- 17.12.2015: <Korn> gets to play important parts in our production

of the Beggars Opera by Bertolt Brecht and Kurt Weill.

- 9-11.04.2016: <Korn> off to Hamburg for the Big Bang Festival.

- 28.10.2016: <Korn> up to Brugge for Iedereen Klassiek.

- 30.10.2016: Korn returned safely from Bruges.

- 01.08.2017: <Korn> taken on the road to Liepaja (Letland).

- 03.08.2017: <Korn> found ok after the 2000 km trip to Letland. It

is expected to return to its homebase on august 10th.

- 09.08.2017: <Korn> returned safely from Liepaja, another 2000 km trip

on rough roads.

- 13.07.2018: <Korn> played the opening of the Ghent Feasts at Sint-Jacobs.

Returned safely.

- 09.11.2018: <Korn> joins the party for the 50th anniversary of Logos...

Rational Melodies, Namuda study #71.

- 17.03.2019: There was some confusion as to the ctrl nr for left-right movement.

The testcode had some bugs in this respect. The controller must be #10 (panning).

- 07.11.2019:<Korn> on the road to Tallinn (Estland)

- 02.07.2021: <Korn> on the road for Luxemburg

- 15.07.2021: Innundations in the abbey where <Korn> is installed...

Awaiting news.

- 19.07.2021: Some pictures received from the robots that got flooded in the

abbey of Neumuenster in Luxemburg:

At first sight it looks

like the cornet and the driver didn't get wet. The electronics underneath

are likely to be lost forever. Certainly the hub board is lost. The wavegenerator

board is mounted vertically but cannot be seen on the picture. The pyrodetectors

for movement sensing are guaranteed to be ruined, as they were mounted very

low on the chassis.

At first sight it looks

like the cornet and the driver didn't get wet. The electronics underneath

are likely to be lost forever. Certainly the hub board is lost. The wavegenerator

board is mounted vertically but cannot be seen on the picture. The pyrodetectors

for movement sensing are guaranteed to be ruined, as they were mounted very

low on the chassis.

- 26.07.2021: <Korn> returned from Luxemburg. First of all we started

by cleaning the entire robot. Removing the thick layer of mud from all electronic

and mechanical parts. Tools used: a toothbrush, a small hard-haired painting

brush, compressed air, a small stainless steelbrush. The motor was found to

be completely stuck. This must be the result of a rusted anchor inside the

stepper. The toroidal transformer mounted underneeth, still contained water

in the windings. However, it was not short circuited. So we connected it to

the mains power -via a safety transformer- to let it get gently warm and thus

to dry it thoroughly.

- 27.07.2021: Continued work on the repair of <Korn>. We also noticed

the bell of the cornet got smashed quite a bit. This cannot be the result

of the innundation however. It must have been mistreated somewhere by someone...

After cleaning the hub board we could bring it to live again. So it survived

the catastrophe. The same revealed true for the dsPIC board for the membrane

driver and the horizontal steppermotor controller.

- 30.07.2021- 23.08.2021: Apparently the motor for the horizontal movement

is not quite healed. We can loosen it with heavy pliers, but after a day or

so it always gets stuck again.

- 24.08.2021: We removed the stepping motor and disassembled it completely.

Internally it was all wet, and this more than a month after the innundations

in Luxemburg. The stator and the anchor were found rusted strongly together.

Trying to repair it by carefully taking all parts apart and thoroughly cleaning

and repolishing of the poles. Here are some pictures of the disassembled stapper

motor: Rotor:

Stator:

Stator:  Bearing

and under mounting plate:

Bearing

and under mounting plate:  Upper mounting plate:

Upper mounting plate:  After assembling again and mounting it in place on <Korn>, the motor

passed all tests again. We expect it to be fully repaired now. The whole repair

procedure took us nevertheless about five hours.

After assembling again and mounting it in place on <Korn>, the motor

passed all tests again. We expect it to be fully repaired now. The whole repair

procedure took us nevertheless about five hours.

14.05.2022: <Korn> up and working, controlled by our 22GHz radar systems,

in Rennes, France.

- 22.07.2023: <Korn> returned safely and in good shape from the tango

production at the Ghent Feasts yesterday.

- 14.09.2023: <Korn> on the road with the robot orchestra for the Zeroth

Law production by Gamut Inc. at the Deutsche Oper Berlin.

- 02.10.2023: <Korn> returned healty and well from its trip to Berlin.

Last update: 2023-10-11

by Godfried-Willem Raes

The following information is not intended for the general public, but is essential

for maintenance and servicing of the robot.

Technical drawings, specs and

data sheets:

The moving upper part can be taken out of the base. First loosen the set screws

on the dented wheel as well as on the ring under the base plate, then pull the

rod out vertically. As an alternative one can also loosen the upper ball bearing

(two M6 bolts) and take out the vertical mechanism. This however requires realignment

of the ball bearing. Then, disconnect the large black rectangular connector.

The wiring is drawn below:

Horizontal Stepping Motor: Sanyo Denko Co. LTD, Step-Syn, type 103-820-2 (IBM

P/N 2526734) DC 4.5 V - 1.4 A, 2 degrees/step. Lot NR. 7749. Asmaat: 9.5 mm.

Drive belt: Gates, Powergrip 180XL.

Vertical Stepping Motor: ASMO, Type 865100-0110 Part number AX020009A, 4 phase,

100 Ohms/winding. Operating voltage: 24 V. Wire colors: white blue black, yellow

orange white. This component was recycled from an old Japanese photocopier.

Asmaat: 6mm, met wormwielvertraging.

MOSFET's: IRL640: Specs: 17 A / 200 V, logic level mosfet. (Ug = 5 V). No cooling

applied. IRLZ44N can be used as an alternative.

Solenoid type used for the valve pushers: Lucas Ledex (now distributed by Saia-Burgess)

STA type 195207-228 (13.8 V DC @ 100% duty), 10 Watt, 7.8 N @ 5mm with 60 degree

plungers. 26 mm diameter, height 52 mm. The required anchor displacement for

the cornet pistons is 16 mm.

Note on the push tubular solenoids used to activate the pistons:

The following specs are valid at 20 degrees Celsius. Maximum holding force

is 29 N

| 13.8V |

100% |

10 W

1.166 A.turns

|

17.78 mm in 41 ms

2 N starting force

|

2.54 mm @ 10 N |

| 19.6V |

50%

max. ON-time: 470"

pulsed: 360"

|

20 W

1.649 A.turns

|

17.78 mm in 32 ms

3 N starting force

|

2.54 mm @ 18 N |

| 28.0V |

25%

max. ON-time: 120"

pulsed: 32"

|

40 W

2.332 A.turns

|

17.78 mm in 22 ms

9 N starting force

|

2.54 mm @ 27 N |

| 44.0V |

10%

max. ON-time: 32"

pulsed: 8"

|

100 W

3.688 A.turns

|

17.78 mm in 15 ms

12 N starting force

|

2.54 mm @ 40 N |

These solenoids may not deliver enough starting force to start the valve movement.

Therefore we could switch them in series with a 14.3 Ohm resistor (10 Watt)

and have a 2200 microfarad electrolytic over them. When we feed the solenoids

from a 24 V supply, the solenoids when firing will see a voltage of 24 V across

them for a time RC= 42 ms, enough to start the movement with a force of about

5 Newton. When energized, the voltage drops to 14 V, enough to hold the valves

pressed down. This was the approach as used in the original design for <So>.

As an alternative, our design for pulse-hold solenoid drivers may be used here.

This was the approach in <Bono>. This approach necessitates a bipolar

power supply. The positive hold voltage can be reduced to 10 V, the negative

velo-pulse voltage should be between 24 V and 36 V. Using this board, the final

circuit becomes a lot smaller than if we used the capacitor discharge circuit.

Motor-compressor driver: taken from power horn, made in Taiwan for Realistic,

type 40-1236C, rated 8 Ohms, 8 Watt.

Ball bearings: Blok Polyamide NR. 1060.225.00 (cost: 43 Euro a piece, 01.2008

at MEA)

Proximity sensors: Pepperl+Fuchs, NJ2-V3-N

Tilt sensor: Penny+Giles STT280/60/P2 (Datasheet: STT

280/60/P2. )

Specifications for the PIC microcode for <Korn>.

Valve lookup tables for <Korn> (according

to acoustic theory)

Power supply:

Modular 230 V ac to 5 V / 1 A DC linear convertor. (microprocessor and logic

power supply)

XP Power module: ECL25US09-E, 9 V / 2.8 A output. (3.64 A peak), for the horizontal

motor driver. [removed 28.10.2010]

Toroidal transformer 230 V - 2 x 22 V, 30 VA (Arabel EK3022)

Toroidal transformer: 220 V with two secondary 12 V windings rated 5 A each.

Wiring & circuit details midihub board:

One super bright 1 W blue LED was used in the first version of this robot.

It is mapped on midi note 125 and controlled by the velo/hold PIC board. These

LED's should be cooled and driven with a constant current limited to 350 mA.

One of the following circuits -using cheap standard TO220 regulators- was to

be used in this robot:

Due to -probably- a spike in the power supply, the LED circuit at some point

short after its installation gave up functioning properly and instead of just

passing away, it showed a very erratic behavior: becoming fully conductive (with

very short current spikes of far over 20 A) and opening up again. This caused

such heavy spikes on the ground lines, that it was the origin of erratic behavior

of the PIC microcontroller. Thus we replaced the circuit with a much simpler

assembly of two times three bright blue LED's connected in series with a 301

Ohms resistor. The total current at 12 V now is only 22 mA. Voltage drop over

each of the blue LED's is 2.9 V.

Output transformer:

High precision wide frequency range MCE toroidal multitap transformer. Type

nr. MCE E217T3F; Order number: 10018709, recycled from an American military

aircraft.

Cornet details:

Builder: Melchior De Vries, Lier. The instrument was made -unfortunately, for

we have an inborn hate for just about anything military- for the belgian armee.

It is marked BS (this is short for Belgische Strijdmacht) an carries the number

K.F.F.K. 14. We have no indication as to the year of construction, but since

the tuning conforms to A=440, we suspect it was made after 1939.

References:

Beauchamp, J.W. "Analysis and Synthesis of Cornet Tones Using Nonlinear

Interharmonic Relationships". In: j-aes, volume 23, number 10, pages 778--795,

1975.

Beauchamp, J.W., "Analysis of Simultaneous Mouthpiece and Output Waveforms

of Wind Instruments" . In: j-aes, 1980, Preprint No. 1626,

Benade, Arthur .H., "Fundamentals of Musical Acoustics". Ed.: Oxford

University Press, 1976.

Fletcher, N.H. & Tarnopolsky, A. "Blowing pressure power and spectrum

in trumpet playing" In: J. Acoust. Soc. Am., volume 105, number 2, part

1, 1999.

Martin, Daniel W., "Lip vibrations in a Cornet Mouthpiece", In: J.Acoust.Soc.Am.

vol13 . 1942

National Semiconductor, LM18298 Dual Full-Bridge

Driver, datasheet. April 1992

Raes, Godfried-Willem, "Kursus Akoestiek", Ghent University College

1982/2014, Internet: http://www.logosfoundation.org/kursus/4023.html

Raes, Godfried-Willem, "Expression

control in musical automates", 1977/2023,

Smith, Bob H., "An Investigation of the Air Chamber of Horn Type Loudspeakers",

in: The Journal of the Acoustical Society of America 25, 305-312 (1953); https://doi.org/10.1121/1.1907038

Robody Pictures with <Korn>:

concert performance:

This motor

is designed for 360 steps for a complete rotation. In this robot, the motor

is driven in microstepping mode at 8 clocks for a single step.

This motor

is designed for 360 steps for a complete rotation. In this robot, the motor

is driven in microstepping mode at 8 clocks for a single step. The light

bulbs and LED's mapped on the midi notes 124 to 127 are also controlled by this

microprocessor board.

The light

bulbs and LED's mapped on the midi notes 124 to 127 are also controlled by this

microprocessor board.

A good default setting

for this controller is 105.

A good default setting

for this controller is 105. Most good sequencer

software (such as Cakewalk or Sonar) use the signed 14 bit format. Note that

one unit of the msb corresponds exactly to a 0.78 cent interval. To convert

fractional midi to the msb only pitchbend to apply follow following procedure:

if the fractional part is <= 0.5 then msb= 63 + (FRAC(note) * 128), if the

fractional part is larger than 0.5, we should switch on the note + 1 and lower

the pitch with msb= (1-FRAC(note)) * 128. Note off does

reset the pitch bend for the playing note!

Most good sequencer

software (such as Cakewalk or Sonar) use the signed 14 bit format. Note that

one unit of the msb corresponds exactly to a 0.78 cent interval. To convert

fractional midi to the msb only pitchbend to apply follow following procedure:

if the fractional part is <= 0.5 then msb= 63 + (FRAC(note) * 128), if the

fractional part is larger than 0.5, we should switch on the note + 1 and lower

the pitch with msb= (1-FRAC(note)) * 128. Note off does

reset the pitch bend for the playing note!

De motor, een type met 360 stappen per omwenteling, wordt bedreven in microstepping

mode aan 8 kloktikken per stap, wat een erg vloeiende beweging mogelijk maakt.

De motor, een type met 360 stappen per omwenteling, wordt bedreven in microstepping

mode aan 8 kloktikken per stap, wat een erg vloeiende beweging mogelijk maakt. De lampjes

en LED's gemapt op de noten 124 tot en met 127 worden ook door deze mikroprocessor

bestuurd.

De lampjes

en LED's gemapt op de noten 124 tot en met 127 worden ook door deze mikroprocessor

bestuurd.

GMT code and just intonation examples for Korn debugged.

GMT code and just intonation examples for Korn debugged.

At first sight it looks

like the cornet and the driver didn't get wet. The electronics underneath

are likely to be lost forever. Certainly the hub board is lost. The wavegenerator

board is mounted vertically but cannot be seen on the picture. The pyrodetectors

for movement sensing are guaranteed to be ruined, as they were mounted very

low on the chassis.

At first sight it looks

like the cornet and the driver didn't get wet. The electronics underneath

are likely to be lost forever. Certainly the hub board is lost. The wavegenerator

board is mounted vertically but cannot be seen on the picture. The pyrodetectors

for movement sensing are guaranteed to be ruined, as they were mounted very

low on the chassis.